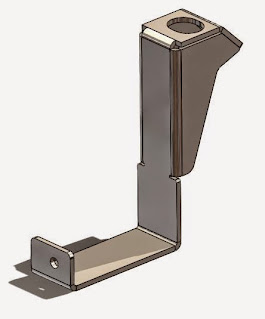

These blocks are used to set the shut height of the tool before stamping parts. These blocks set the deepest point that the tool can travel down at the bottom of the stroke. The top die shoe should never hit these blocks. The die shut height should be set about 0.010 or more above these blocks.

When the tool is in storage, the upper unit of the tool could rest on these blocks.

These blocks also have a purpose as safety blocks. They can protect expensive tooling components in case the tool is over stroked and go deeper than intended.

There are unfortunate events when the press could go deeper. This could happen at the setting time by accidentally adjusting the RAM to go too deep. As a result, the press and the tool jams. It is not an easy task freeing the tool and the press. On many occasions, the components require to be cut. Jamming could happen during production as well, even the shut height was set properly before. From impact hits and vibration, the RAM adjustment locking nuts may get loose and the RAM may go further down without being noticed. To undo a jammed tool and press is time consuming and expensive, also resulting in valuable downtime.