The picture shows the bottom die set and

some of its components are being inspected,

aligned and assembled.

Ball bearing guided high precision progressive tool for high speed automated production

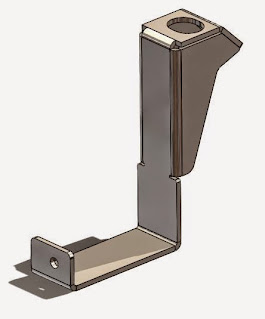

Stamped metal parts usually require more than one operation in one. This progressive metal stamping tool produces a high volume mounting bracket that pierces holes, blanks out a shape by cutting the strip into separate parts and finally folds the part into an L shape. At each hit a final product falls off at the end of the tool. It is made for a high production automated punch press using coil and an air feeder for continuous operation.

This progressive die design consists all the necessary features that any stamping tool should have from ease of use through high accuracy to reliable operation for a long time. It includes strip feed and guide, stripping, slug separation, and feeder actuation. As an option the tool can be used as a manually operated tool without the air feeder using strips instead of coil.

The cutting components are designed to be made of hardened tool steel that ensures the long usability. Choosing the right alloy for the application and the proper design of the tool can greatly effect the life of the tool. As a result it can operate trouble free for longer, saving on maintenance. It can also reduce or eliminate downtime and minimize costs that are associated with the value of the final product.

The progressive tooling was designed using SolidWorks 3D CAD. Shop drawings, and files generated from the models are seamlessly fit into any machine shop or tool room's profile.