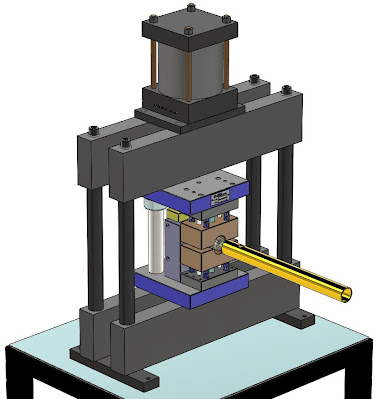

Air to oil powered three platen punch press

Air to oil powered three platen press product line is the most versatile of all the portable and modular presses offered by Vortool Manufacturing. It is well suited for steel rule die tooling, or to process e.g. aluminum extrusion punching, using multiple stations.This combination press / four post tool also called the "Three Platen Punch Press" is accessible from all four sides. Multiple work stations can be mounted inside or around the perimeter of the press to utilize maximum usability while lowering the tooling cost per station at the same time.

• A wide selection of sizes available from a miniature of 4" x 6" inner work area to 36" x 36" or larger custom specified dimensions and anything between.

• Tooling could be mounted directly to the detachable transfer plates.

• The four post precision guide system ensures superior tooling alignment for punching, piercing, notching, blanking or forming.

• The power source could be as small as a 200 lbs capacity compact air cylinder for the smallest model, or it can be as powerful as your application needs it to be, using hydraulic power for up to 80 tons.

• The unit can be directly mounted on a bench top, or shipped with a dedicated stand. The stand could be anchored to the floor or have lockable casters for even grater mobility.

• The operator control is also fully customizable from our standard two push button system with anti tie down module* to a foot pedal, a pedestal style, or a non contact finger sensor system.

• As part of the custom options, when the part(s) are nested and are in the correct position, the press can be activated automatically. There may be a selectable PLC controlled operating system to cover all variations of your process.

• Safety devices are available from simple physical guards to light curtains to keep the operator(s) safe and meet any government or company standard.

• The material that is used for the press' components could be steel, aluminum or stainless steel, whether the press is used in a general factory environment, in a medical facility or in the food industry.

*Anti tie down module: It is a safety device that controls how the two push buttons function. The buttons must be pressed at the same time within few milliseconds. If one button pressed only or one button pushed after the other, the system will not activate. The operator’s both hands are occupied while the press is being activated and is in motion.