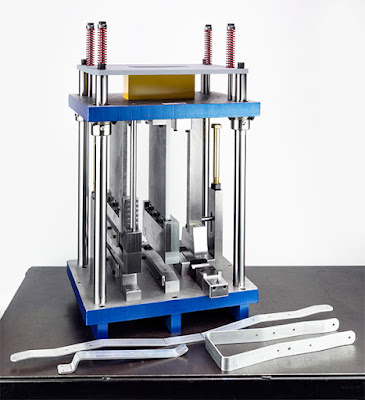

A three station rotary bender forming tool was designed and manufactured by Vortool Manufacturing. Made in Canada.

This form tool is the second tool for the part operation. The previously stamped aluminum flat bars are being bent here in three side by side stations.

The tool's foot print is 16" x 28". The nearly 33" long flat bar needs to be bent into a kind of "U" shape, so the tool require enough inner space for the part to fit once bent. The overall height of the tool is 32 inches. The tool is designed to operate in a 50 ton hydraulic "H" frame press.

The first station in this tool is to process the shorter part that was made with the previous tool. The required shape was being done in a single stroke.

The longer part needed two stations. In the middle station the two ends of the aluminum flat bar was bent at 3 places. The third station was designed and built to bend the parts to a "U" shape with 18 degrees over bend.

Standard wipe form style tooling could bend only up to 90 degrees or rather less as most material has some degree of spring back. This rotary bender employed a custom designed and built pair of rotary benders, allowing a great amount of over bend.

The tool has 6 lifter springs on top to automatically open the tool after each stroke. Most "H" frame presses use a bottle jack style hydraulic cylinder, so it can push things downward but can't pull. The auxiliary springs overcome this problem and lift the tool to open position by default.