Custom oil to air mandrel punch press station for aluminum tubing video by Vortool Manufacturing.

Custom oil to air mandrel punch press station for aluminum tubing

Custom oil to air mandrel punch press station for aluminum tubing video by Vortool Manufacturing.

Custom portable air-oil cylinder / shop air punch press station

Custom portable air-oil cylinder / shop air punch press station

Operating the 7 ton air-oil cylinder punch press and multi station die tooling for punching holes in aluminum tubes video.Designed and manufactured by Vortool Manufacturing.

0.8 ton custom table top pneumatic press

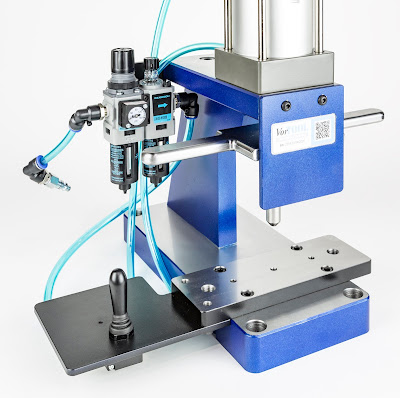

Custom Benchtop Pneumatic Press

This custom benchtop pneumatic shop air press is designed to push down ram by hand to pre-align before striking with full air power. No electrical power required, only compressed shop air.

Designed and manufactured by Vortool Manufacturing.

Contact us if you are interested in having something similar designed and made for your specific needs.

- 0.8 ton

- Air cylinder bore: 3.15"

- Air cylinder stroke: 3.94"

- Air pressure: 130 psi max, adjustable by FRL

- Base to RAM distance: 3.6"

- Operated by a toggle switch

- Weight: 75 lbs

- Dimensions: 14 x 16 x 19"

Designed and manufactured by Vortool Manufacturing.

Contact us if you are interested in having something similar designed and made for your specific needs.

Flatten, trim, punch and bend stainless steel pipe tool and die design

Flatten, trim, punch and bend stainless steel pipe tool and die design

This custom-built to order multi-station round pipe or tube tool and die combines four separate operations. The process of tube flattening involves using the force of the press to push the pipe or tubing against a die, making the tube to conform to the shape of the die. Parts of the tooling is made of hardened steel or tool steel to maintain and prolong the tool's life.Flattens the end of the tube or pipe. The process of tube flattening involves using the force of the press to flatten the pipe.

Bends the end of the already flattened tube or pipe

Trims the end corners in a radius of the already flattened and bent tube or pipe

Punches a hole at the flattened end of the tube or pipe for to be able to fasten it to other components

This tube die is placed in a press to make the finished parts. There are steps to follow and there are interchangeable elements to make all variations of making the final product.

This multi-station tool also comes with a jig to check the correct length of the product to achieve and check the consistency. It helps with quality control.

This tool and die was designed and manufactured by Vortool Manufacturing.

Subscribe to:

Comments (Atom)