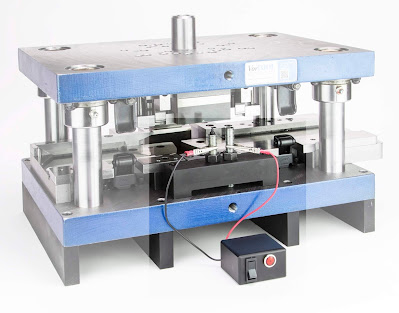

Improve your mass production process by using specialty jigs and fixtures. Hold and guide your work pieces. Specialty jigs and fixtures provide repeatability, accuracy and interchangeability in your manufacturing process to duplicate parts. We can design and manufacturer your custom jigs and fixtures for your machinery.

Specialty jigs

Special device that holds, supports, or is placed on a part to be machined. It holds and guides the work piece. Drill jigs are used for drilling, tapping, reaming, chamfering, counter boring, countersinking, and similar operations.Specialty fixtures

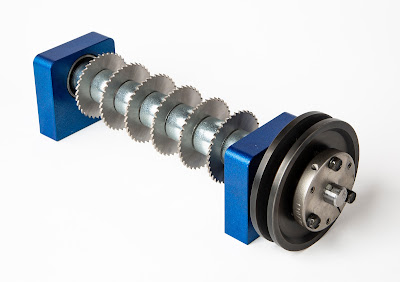

Production tools that locate, hold and support the work securely, so the required machining operations can be performed. Fixtures help simplify metalworking operations performed on special equipment. Examples of the more-common fixtures include milling fixtures, lathe fixtures, sawing fixtures, and grinding fixtures.• Milling fixtures

• Surface-grinding fixtures

• Lathe fixtures

• Cylindrical-grinding fixtures

• Mechanical-assembly fixtures including threading, riveting, stapling, stitching, pinning, etc.)