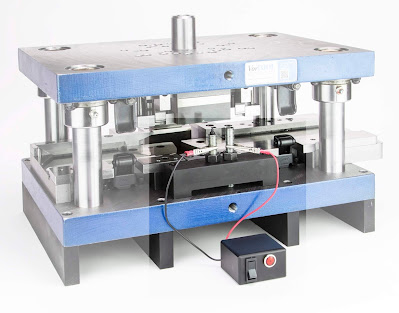

Electronic Die Shut Height Finder

Part No. EDSHF 2201The Electronic Die Shut Height Finder can be used with any die tool that already have the Shut Height Rod Retainer unit, so you may need only one Electronic Die Shut Height Finder at your facility.

- Dimensions: 1.5" x 2.625" x 2.25"

Includes switch, lamp, two gator clips and a 9V battery.

To test this unit: Turn switch on and contact the two gator clips to each other. The lamp on the unit should lite up. If the lamp does not lite up, change battery.

Removing battery: Remove the rear cover plate by unscrewing the two Philips head screws. Slide the battery out and remove it from the contact base.

Die Shut Height Rod Retainer

Part No. DSHRR 2202The Die Shut Rod Retainer unit is a dedicated device, specific to a metal stamping die. Each stamping tool should have one and installed.

- Dimensions: 1.5" x 1.5" x (6.25" or custom sizes are available)

- Material: Black Delrin and steel

- Limit Stop: ½-13 x (custom) based on Shut Height.

- Material: Steel Rod Switch: ½-13 x (custom less 0.75 than Limit Stop).

Includes a long nose 5/16-18 steel spring plunger with Nylock.