- Low volume part production

- Laser cut metal parts

- Four edges of the laser cut part is bent in bending tool and die. Three of the part edges has a 90 degree angle. The forth edge has a different angle.

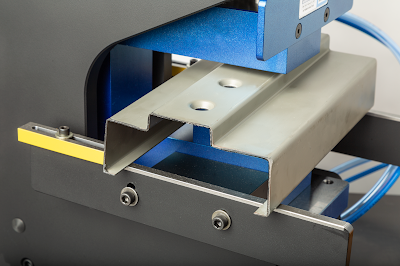

Edge bending tool and die of laser cut parts

Edge bending, or wiping die bending is achieved by holding the sheet between a pad and die than sliding the wiping flange across the face and bending the sheet metal which sticks out.

Bending tool and die

Footprint: 10" x 18"

Storage height: 7.2

Weight: 205 lbs

Folding tool and die

This tool and die bends parallel axis at both edges of the stock forming a cable mounting bracket.

Bending tool and die

This bending die transforms a strip of straight copper to have a curved shape in the middle.

The bending die in the middle is interchangeable sizes to create three different radiuses.

The length of the strip is adjustable with a sliding track.

C-frame punch press and dimple hole stamping tool and die for metal door frames

Multicyl cylinder C-frame punch press

- Air over oil “C” frame bench top punch press

- Tonnage (output): 12.5 ton capacity at 120 psi

- Power requirement: compressed air, 90-120 psi

- Operator control: Foot pedal

- “M” style quick connect to air supply

- FRL to filter air supply, regulate air pressure and lubricate

Metal stamping tool and die

- Punching single dimple holes in 16 – 14 ga thick metal door of different profile sizes, up to 9-1/2 frame

- Tool is easily removable from the press and can be replaced with different sizes if needed.

Cardboard perforating tool and die

Stamping tool and die punches 100 holes in thick corrugated cardboard.

Subscribe to:

Comments (Atom)