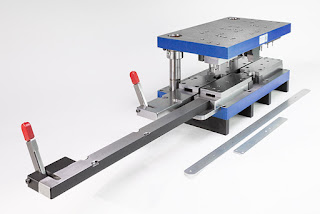

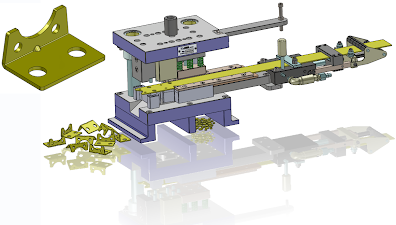

Flatbed die cutting press and steel rule die to cutout material into custom shapes and designs

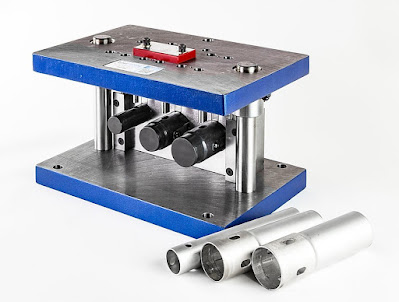

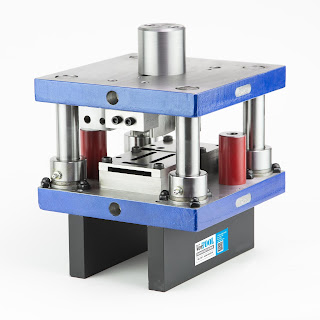

Cylinder: Multicyl 7.5 tons capacity, 5/8 overall stroke, 9/32 power stroke

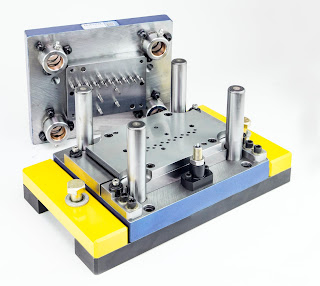

Structure: Three platen, four post, precision guided die set with pre-set cut depth

Connection type to air in: “M” style quick connect

Total height: 33.5

Weight: 250 lbs

Power source: Compressed air, 120 psi (max), set to 100 psi by mounted FRL.

Press style: Bench mount with adjust able height platforms

Operator control: Two push buttons

Feed in/out: Manual, visually controlled, rolls or individual blanks or sheets

Foot print: 14.75 x 17.375